- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What Is a Cradle Reel Elevator and Why Is It Important?

Cradle Reel Elevator refers to specialized mechanical equipment designed to lift, support, and position heavy reels — especially cable reels — during installation, stringing, transport, or handling operations. This advanced reel handling solution plays a crucial role in power transmission, telecommunications, construction, and industrial settings where cables and wired materials must be deployed safely and efficiently.

In this guide, we explain the purpose, mechanics, benefits, and real-world applications of cradle reel elevators. We also tie in how manufacturers like Ningbo Lingkai Transmission Equipment Co., Ltd. contribute to improved cable logistics solutions around the world.

Article Summary

This article explores cradle reel elevators from multiple angles: basic definitions, engineering principles, industry applications, design differences, and buyer considerations. You’ll get answers to key industry questions and practical insights for application in utility, telecom, and industrial projects.

Table of Contents

What Is a Cradle Reel Elevator?

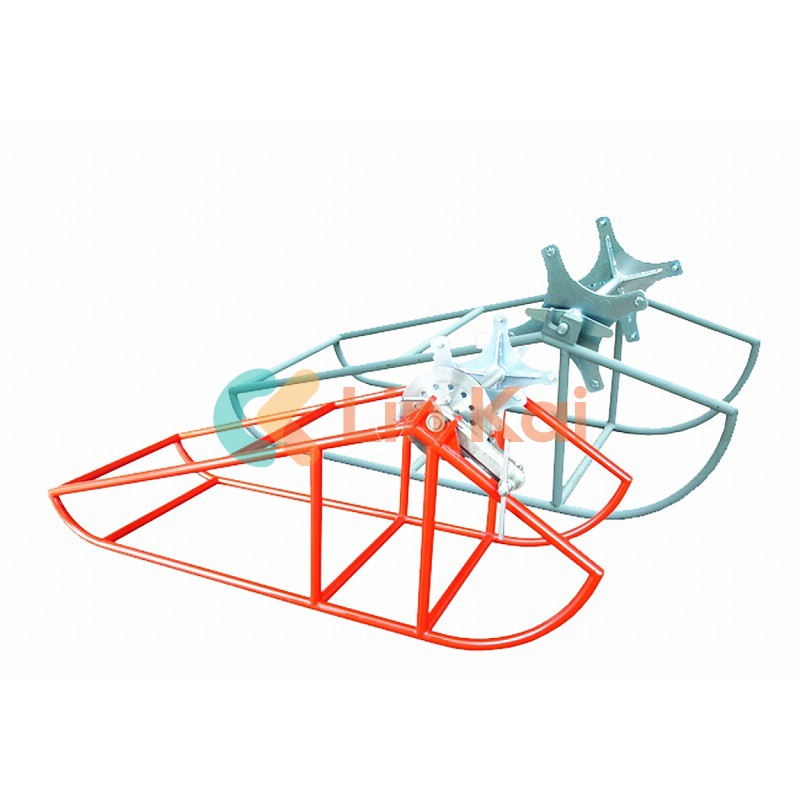

A cradle reel elevator is a piece of lifting and handling equipment specifically engineered to support and elevate reels or drums containing cable, wire, rope, or similar materials. It typically features a cradle-like support framework that securely holds the reel while enabling controlled vertical movement.

Unlike generic hoists, cradle reel elevators are purpose-built for cable handling, reducing material stress and operator risk while improving workflow efficiency in challenging field environments. They are often paired with cable pullers, gin poles, or other transmission line tools.

How Does a Cradle Reel Elevator Work?

Cradle reel elevators operate by:

- Providing a stable cradle platform to engage the reel drum securely.

- Using manual, mechanical, hydraulic, or powered lifts to raise the reel to the required position.

- Allowing the reel to be rotated or unwound during deployment or stringing operations.

This mechanism ensures reels are lifted straight and remain stable in vertical or near-vertical orientations, mitigating risks of reel tipping, wire snags, or cable damage.

Where Are Cradle Reel Elevators Used?

Cradle reel elevators are widely used in:

- Power transmission line installation and maintenance

- Telecommunications cable deployment

- Construction and infrastructure projects

- Heavy material handling yards

- Utility and grid restoration operations

In these contexts, they provide an efficient way to support cable reels during payout, tensioning, and reclaim operations.

Why Choose a Cradle Reel Elevator?

Compared to other reel handling methods like makeshift stands or forklift-only lifting, purpose-built cradle reel elevators offer:

- Safety: Secure positioning reduces accidental reel movement.

- Durability: Heavy-duty construction withstands field demands.

- Efficiency: Easier setup and handling means less downtime.

- Versatility: Can handle a range of reel sizes and weights.

Leading suppliers like Ningbo Lingkai Transmission Equipment Co., Ltd. have built expertise in delivering reliable, ISO-certified cable handling solutions tailored for industrial requirements.

What Are Key Design Types and Features?

Cradle reel elevators vary in design based on capacity, operation method, and field application. Typical considerations include:

| Feature | Description |

|---|---|

| Load Capacity | Ranges from lighter reels for pilot wire (dozens of kg) to large ACSR and telecom reels (hundreds of kg). |

| Lift Mechanism | Manual hand pump, hydraulic lift, or powered motorized system |

| Adjustability | Width and diameter adaptability for reels of various sizes |

| Portability | Foldable or trailer-mounted units for easier field transport |

| Safety Features | Braking systems or locking pins to prevent reel slip during deployment |

Design features are key to equipment suitability in different project environments. Manufacturers like Ningbo Lingkai Transmission Equipment Co., Ltd. often provide customization based on project specifications.